Wellhead Components Products

Casing Head Housing

The casing head in a conventional wellhead system is the lowest part of the wellhead assembly andis almost always connected to the surface casing string.

It supports the remaining parts of the wellhead and completion equipment.

The casing head housings seal off the surface casing by means of Slip-On-Weld (SOW) Slip-On-Lock (SOL) or threaded connection.

Specification: API 6A

Top Flanged Size Range: Up to 21-1/4“

Working Pressure Range: Up to API 5000 PSI

PSL: 1, 2, 3, 3G PR: 1 & 2

Material Class: AA , DD

Temp. Rating: P + U

NACE MR0175/ISO 15156 complianc

Casing Head Spool

The casing spool in a conventional wellhead system is the component that allows for an additional string of casing to be set in the well.

Depending on the casing program for the well, there can be one or more casing spools.

Specification: API 6A

Top Flanged Size Range: Up to 16-3/4“

Working Pressure Range: Up to API 10,000 PSI

PSL: 1, 2, 3, 3G

PR: 1 & 2

Material Class: AA , DD

Temp. Rating: P + U

NACE MR0175/ISO 15156 compliance

Tubing Head Spool

The Tubing Head is the top spool on a surface wellhead. It is typically installed over the last string of pipe suspended in the well, the production casing. These heads come in a wider range of types and sizes than any other head in a conventional wellhead system. The Tubing Head will provide for well fracturing and allow for the well to be completed using an almost innumerable variety of tubing hangers and tubing head adapters.

Specification: API 6A

Top Flanged Size Range: Up to 13-5/8“

Working Pressure Range: Up to API 10,000 PSI

PSL: 1, 2, 3, 3G

PR: 1 & 2

Material Class: AA ~ HH

Temp. Rating: P + U

NACE MR0175/ISO 15156 compliance

Non-Auto Casing Hangers

Non-Auto casing hanger is designed for general service where control of annulus pressure in the casing head bowl is not critical. Sharp hardened inner teeth support suspended casing weight up to 60% of the pipe body yield strength. A minimum weight of only 5000 lbs, is required to initiate hanger operation.

Specification: API 6A

Casing Size Range: 7”, 9 5/8”, 13 3/8“

Working Pressure Range: Up to API 5000 PSI

PSL: 1, 2, 3, 3G

PR: 1 & 2

Material Class: AA , DD

Temp. Rating: P + U

NACE MR0175/ISO 15156 compliance

Auto Casing Hangers

Auto casing hanger is designed for critical service and deep well completions where high casing weights place an unacceptable strain on conventional slip mechanisms.

The integral sealing element is automatically energized with release of the casing weight. A tooth profile on the back of tapered slip elements help restrict radial loading and increase ultimate capacity casing hangers are capable of supporting 80% of the pipe body yield strength.

Specification: API 6A

Casing Size Range: 7”, 9 5/8”, 13 3/8“

Working Pressure Range: Up to API 5000 PSI

PSL: 1, 2, 3, 3G PR: 1 & 2

Material Class: AA , DD

Temp. Rating: P + U

NACE MR0175/ISO 15156 compliance

Tubing Hanger

Tubing Hangers Straight profiles allow for greater suspended tubular loads with out exceeding hoop stress design criteria in the wellhead body.

Tubing Hangers are provided with "H" back pressure valve for use in well control during completion and workover operations. the feature of extended neck design to isolate wellbore fluids and protect the API ring seal from damage or corrosion.

Seals are mechanically energized with the tubing head lockscrews. Tubing Hangers have an additional feature of two control line ports to the extended neck model.

Specification: API 6A

Tubing Size Range: 2-7/8”, 4-1/2”, 5-1/2“, 7“

Working Pressure Range: Up to API 15,000 PSI

PSL: 1, 2, 3, 3G PR: 1 & 2

Material Class: AA ~ HH

Temp. Rating: P + U

NACE MR0175/ISO 15156 compliance

Wear Bushing &

Running/Retrieving Tools

While drilling the well, it is required that the seal bores in each of the

intermediate casing head/casing spools and tubing head/tubing spools

be protected. Wear Bushing is designed and used to preventing cavity

sealing surface of casing head and casing spool from damaging during

drilling operation.

Wear bushing is installed and removed by Running/Retrieving tool.

Back Pressure Valve & Running/Retrieving Tools

The type H back-pressure valve is used to seal the tubing

pressure up to 15,000 psi while the blowout preventors are

removed and the Christmas tree is installed. It also allows

fluid to be circulated down the tubing and prevents backflow.

A two-way check valve is designed to fit the same profile as

the BPV. It holds pressure from both directions while allowing

equalization when required and is used to test the tree and

BOP assembly.

Back Pressure Valve Lubricator Tool

back pressure valve lubricators are used to safely facilitate

the installation of back pressure valves (BPV) or two-way check

valves (TWCV) into a wellhead tubing hanger. Used in wellhead

and tree intervention & repairs, this will isolate and contain

wellbore pressure.

Wellhead Control Panel

BJ control panels are available in a wide variety of options and are built with exceptional quality with a proven track record for reliability and ease of maintenance. We specialize in the design and assembly of wellhead surface and sub-surface safety valve & HIPPS control panels for well production facilities.

Our panels are adaptable to facilities located both onshore and offshore and are designed and assembled in-house in both standard and custom configurations. Each well has individual manual and automatic control features to allow the well to be shutdown in sequence according to the pneumatic logic control or program logic

control (PLC).

To achieve this, the Wellhead Control Panel/Rack consists of various pressure switches, sensors and solenoid valves.

Remote Monitoring & Control

Where required, WHCPs can be provided with REMOTE STATUS monitoring of important parameters from Process Platform as well as the facility for REMOTE CONTROL of shutdown valves.

Manual ESD Fusible Plug Loop Charging

ESD and Fusible Plug Loop Charging Facility with Loop Status and Alarm Indication is designed to provide for minor loop leakages.

Hydraulic Power Unit

The HPU can be integrated in the common section of the panel complete with pneumatic/electric driven pumps, accumulators, reservoirs, thermal and pressure relief optimally sized to provide actuating power to all hydraulically operated shutdown valve.

Air/Gas Supply System

Duplex air filter and pressure regulators are provided with Inlet/Outlet Pressure Indication and Low Pressure Alarm (where required) to handle the total Air/Gas requirments. A separate duplex regulator station is provided for supplying instrument air to the logic system.

Construction Features:

The most durable and corrosion resistant materials are used throughout keeping in mind the difficult environmental conditions encountered on offshore platforms. The panels themselves are, made of SS316L stainless steel, all welded construction, with full-length hinged swing rear door arrangements with heavy-duty 3-point T-bar latch with handle and lock.

Spool and Adaptor Spool

Behsazan Jonoob design and manufactures Spacer and Adaptor Spools with high quality forged material and pipes in all sizes and pressure ratings suitable for Wellhead Extension, BOP, Spacing and Choke, Kill, and Production Manifold applications.

Specification: API 6A

Nominal Sizes: 1 13/16" ~ 21 3/4"

Rating: 2000, 3000, 5000, 10000

M/C: AA to HH

T/R: K, L, N, P, S, T, U, V

Material: 45K, 60K, 75K

PSL: 1, 2, 3, 3G

PR: 1, 2

Suitable for Sour service,

NACE MR0175/ISO 15156 compliance

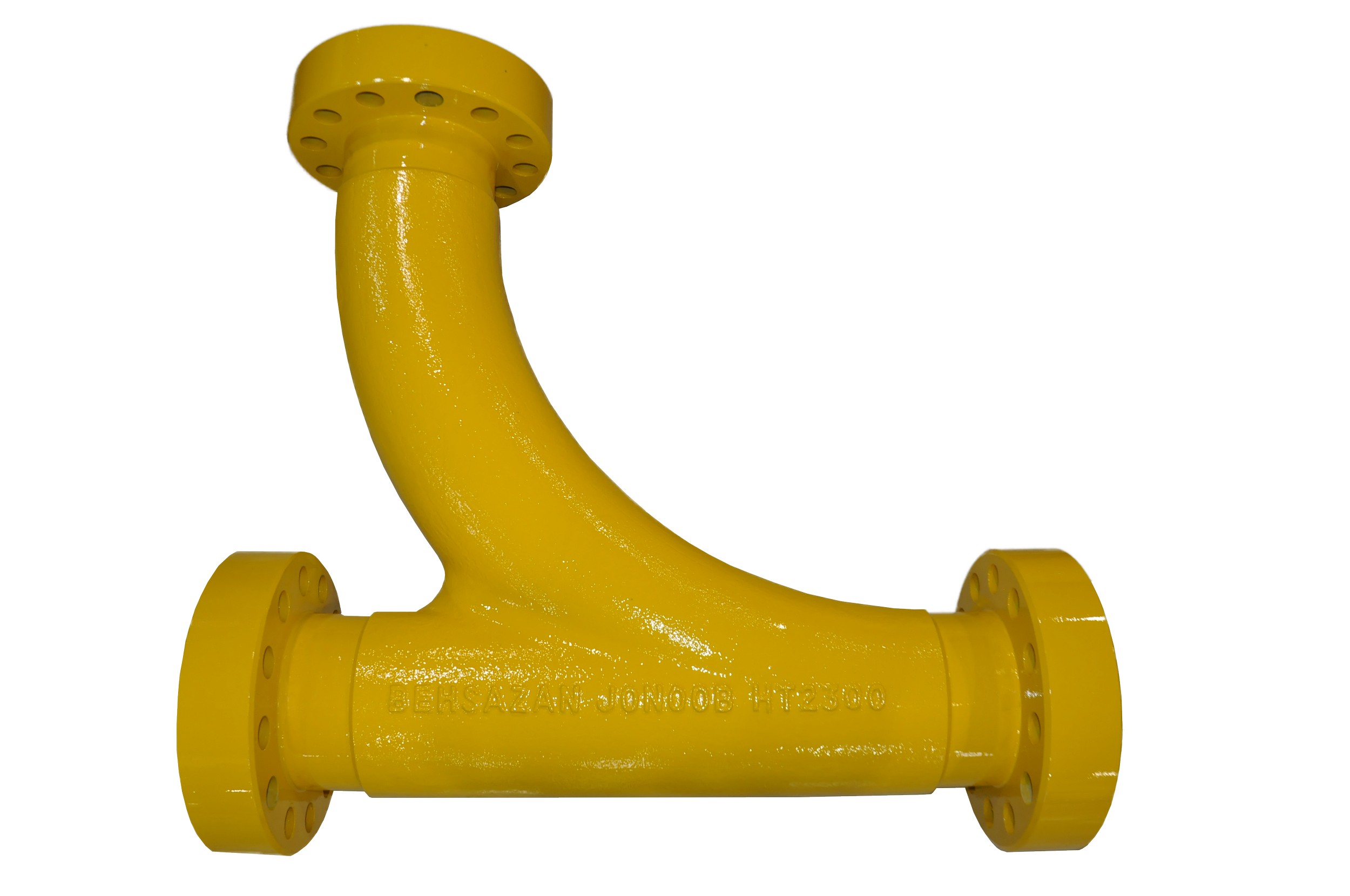

Sweep Bend

Behsazan Jonoob manufactures different sizes and working pressures of Sweep Bends with Hot Bend process using high quality seamless pipe and Casting.

Specification: API 6A

Nominal Sizes: 1 13/16", 2 1/16", 3 1/8", 4 1/16", 7 1/16"

Rating: 3000, 5000, 10000

Material: Forged and Cast

Suitable for Sour service,

NACE MR0175/ISO 15156 compliance

Flanges

Specification: API 6A, ASME B16.5 and ASME B16.47

Type: Weld Neck, Blind, Threade, Socket Weld

Nominal Sizes(API 6A): 1 13/16"~21 1/4"

Rating: 3000, 5000, 10000, 15000

M/C(API 6A): AA to HH

T/R(API 6A): K, L, N, P, S, T, U, V

Material: 45K, 60K, 75K

PSL: 1, 2, 3, 3G

PR: 1, 2

Nominal Sizes (ASME B16.5): 1/2"~24"

Nominal Sizes (ASME B16.47): 26"~60"

ANSI Class: #150, #300, #600, #900, #1500, #2500

Overlay/Cladding: lnconel

Suitable for Sour Service, NACE MR0175/IOS 15156 compliance

Double Studded Adapter (DSA)

Behsazan Jonoob manufactures different type of Adapter Flanges consist of: DSA, SSA and Flange X Union in all sizes and pressure ratings. BJ Eng Flanges have minimum overall heights, or customer specified thicknesses, consistent with design considerations.

Specification: API 6A

Nominal Sizes: 3 1/8" ~ 21 1/4"

Rating: 2000, 3000, 5000, 10000

M/C: AA to HH

T/R: K, L, N, P, S, T, U, V

Material: 45K, 60K, 75K

PSL: 1, 2, 3, 3G

PR: 1, 2

Overlay/Cladding: lnconel, SS316L

Suitable for Sour Service,

NACE MR0175/ISO 15156 compliance

Double Studded Adapter (DSA) Packoff Flange

Double Studded Adapter (DSA) Pack-off Flanges are designed to fit over wellbore

casing and provide an auxiliary seal. With the flange in place, a jump in pressure

rating can be achieved in a minimum of space. The flange allows the operator to test

between the flange and the annular seal in the section above or below.

Specification: API 6A

Nominal Sizes: 3 1/8" ~ 21 1/4"

Rating: 2000, 3000, 5000, 10000

M/C: AA to HH

T/R: K, L, N, P, S, T, U, V

Material: 45K, 60K, 75K

PSL: 1, 2, 3, 3G

PR: 1, 2

Overlay/Cladding: lnconel, SS316L

Suitable for Sour Service,

NACE MR0175/ISO 15156 compliance

Cross and Tee

Behsazan Jonoob design and manufactures Flanged and Studded Crosse and Tee according to API Spec 6A with high quality forged material.

Specification: API 6A

Nominal Sizes: 1 13/16", 2 1/16", 3 1/8", 4 1/16", 7 1/16"

Rating: 3000, 5000, 10000

M/C: AA to HH

T/R: K, L, N, P, S, T, U, V

Material: 45K, 60K, 75K

PSL: 1, 2, 3, 3G

Suitable for Sour Service,

NACE MR0175/ISO 15156 compliance