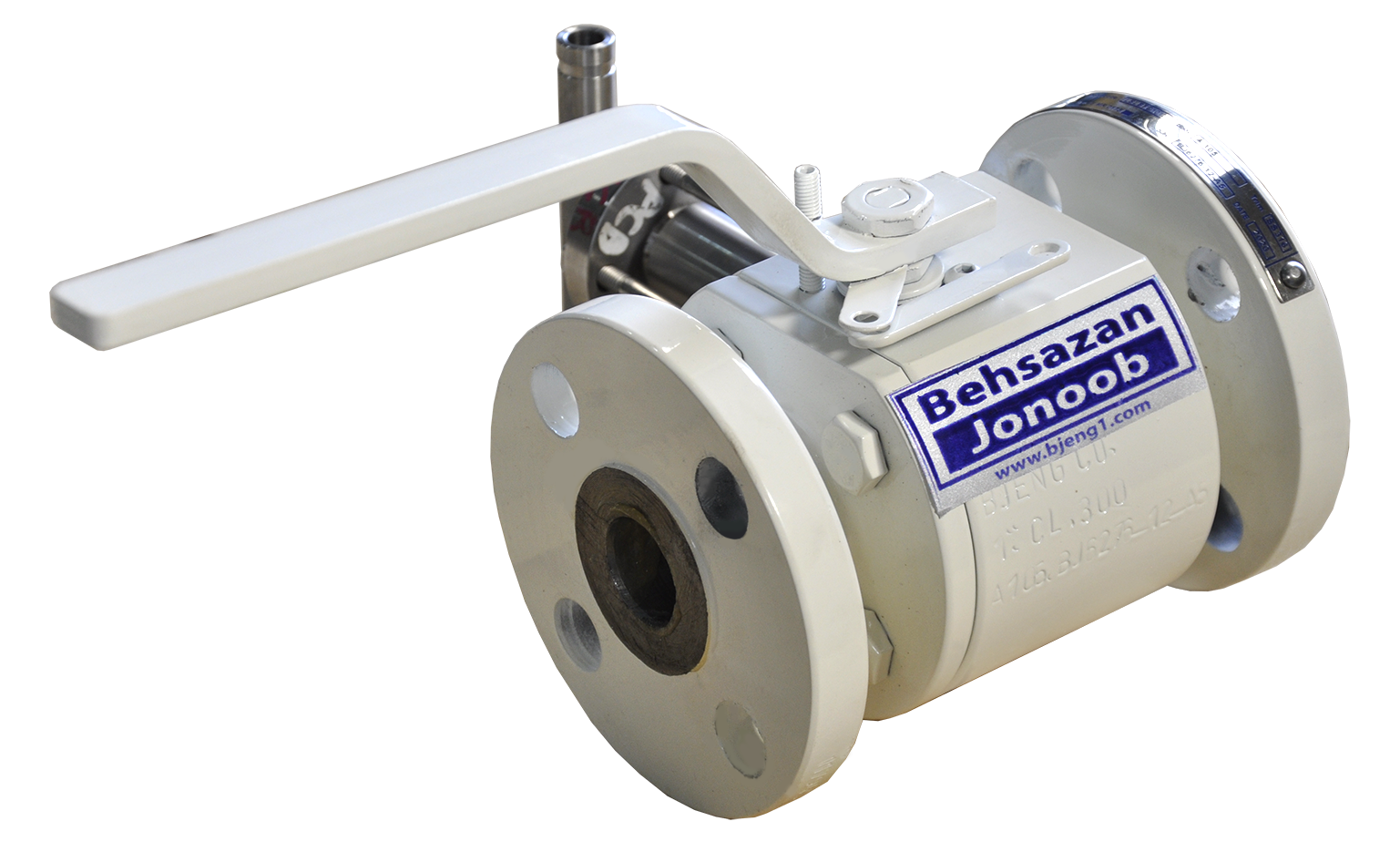

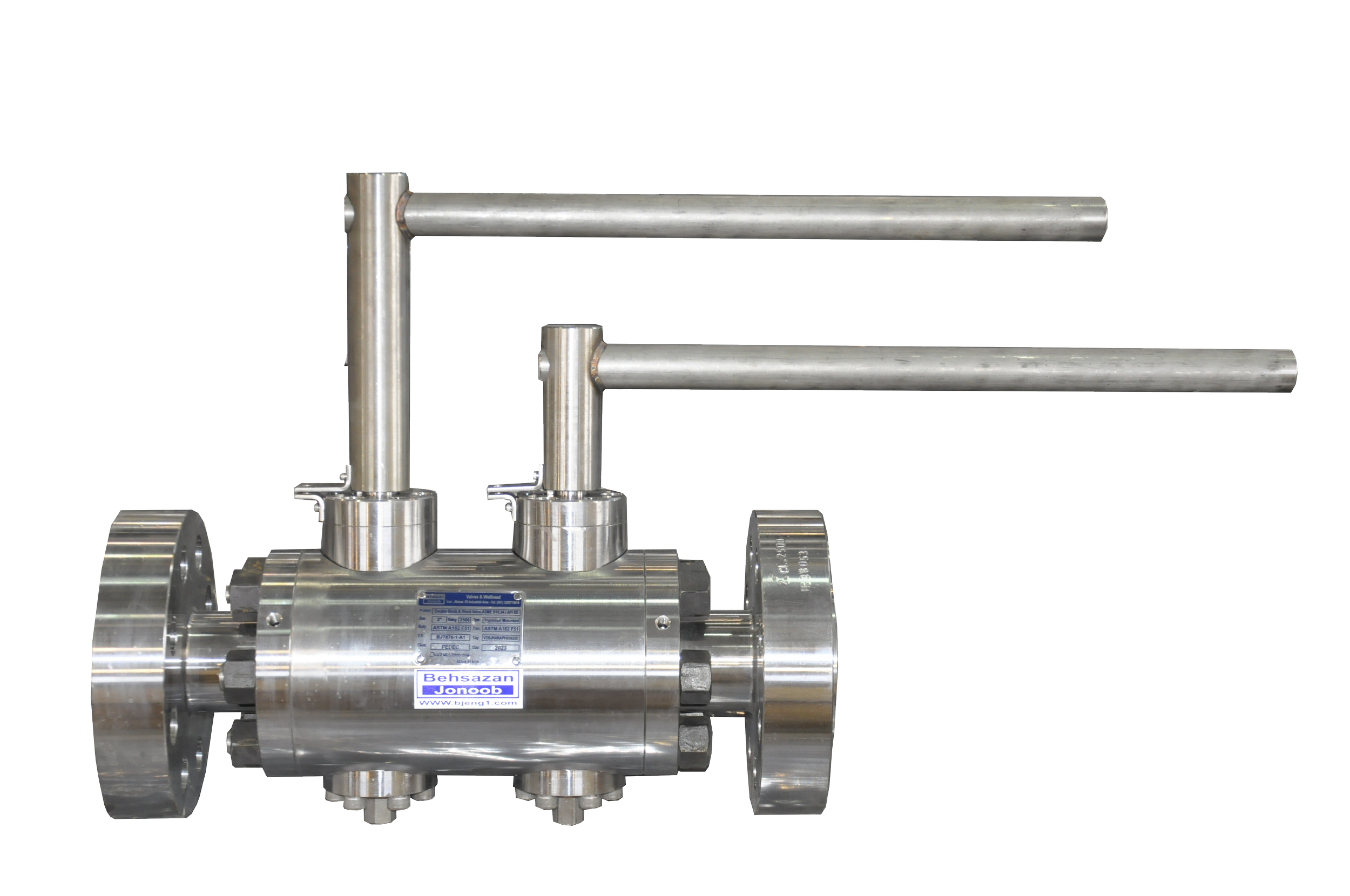

Single & Double Block and Bleed Valve

A Block and bleed Valve is a hydraulic manifold that combines one or more block/isolate valves, usually ball valve, and one or more bleed/vent valves, usually ball or needle valves, into one component for interface with other components (pressure measurement transmitters, gauges, switches, etc.) of a hydraulic (fluid) system. The purpose of the block and bleed manifold is to isolate or block the flow of fluid in the system so the fluid from upstream of the manifold does not reach other components of the system that are downstream. Then they bleed off or vent the remaining fluid from the system on the downstream side of the manifold.

Behsazan Jonoob Double Block and Bleed (DBB) Valve are designed, engineered and manufactured especially for oil and gas pipeline application. Manufactured at our API certified facility, all BJ DBB Valves provide excellent corrosion resistance and superior sealing performance at both high and low pressures. BJ offers a wide variety of material options to meet your critical needs from Carbon Steel to Super Duplex Stainless Steel and Inconel, available in a broad range of sizes and ratings. BJ DBB Valves are equipped with standard features of Double Block & Bleed, Fire Safe, NACE MR0175 compliance and ISO mounting pads to all bare stem valves for gear or actuator adaption.

Specification: API 6A, API 6D, ASME B16.34, ISO 17292

Type: Ball, Gate, Needle

Nominal Sizes(API 6A): 1-13/16" ~ 7-1/16"

Rating: 3000, 5000, 10000

Nominal Sizes(API 6D): 1/4" ~ 8"

ASME Class: #150, #300, #600, #900, #1500, #2500

M/C(API 6A): AA, BB, CC, DD, EE, FF, HH

T/R(API 6A): K, L, N, P, S, T, U, V

PSL(API 6A): 1, 2, 3

PR(API 6A): 1, 2

Material: Carbon Steel, Low Alloy Steel, Stainless Steel, Nickel Alloy, Super Duplex

Service: General, Sour Service, Severe Sour Service, Cryogenic and High Temp. Service

NACE MR0175/ISO 15156 compliance